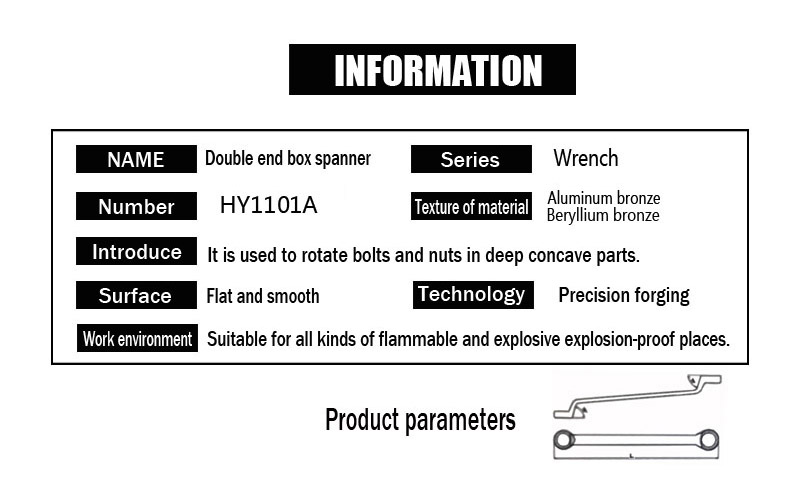

Wrench,double box offsetHY1101

Product introduction:Explosion proof double end box spanner is used for fastening and removing hexagon head bolts and nuts, especially suitable for narrow and concave space which can not accommodate double headed solid wrench.

Product material:Aluminum bronze, beryllium bronze.

Place of Origin:Dongguang, Cangzhou, Hebei. TEL:+8619933756239 WhatsApp/WeChat:19933756239

|

Non-sparking wrench is the most widely used and frequently used hand tool in Non-sparking tools. Non-sparking spanners include Non-sparking adjustable spanner, Non-sparking double end box spanner, Non-sparking double end solid spanner, Non-sparking solid box spanner, Non-sparking percussion solid box spanner, Non-sparking high neck percussion solid box spanner, Non-sparking convex percussion solid box spanner, Non-sparking curved handle percussion solid box spanner, Non-sparking valve spanner, Non-sparking hexagon spanner, Non-sparking F-type spanner, Non-sparking hook spanner Non-sparking open barrel wrench, Non-sparking ratchet wrench, etc. The non-sparking wrench of aluminum bronze, the specific material is high-purity electrolytic copper as the base, adding nickel, aluminum, manganese, iron, and other metals to form an alloy. Copper alloy (commonly known as beryllium bronze) is a non-sparking wrench. The specific material is high-purity electrolytic copper as the matrix, adding appropriate amounts of beryllium, nickel, and other metals to form a copper-based alloy. The thermal conductivity and electrical conductivity of these two materials are excellent. The hardness and wear resistance of aluminum bronze after heat treatment is almost the same as beryllium bronze and can reach more than HRC30o. Beryllium bronze has no magnetism and can be used in strong magnetic fields. Beryllium bronze alloy and aluminum bronze alloy do not generate sparks during impact or friction. They are very suitable for manufacturing safety tools used in explosive, flammable, intense magnetic, and corrosive situations. Non-sparking wrenches made of aluminum bronze and beryllium bronze can be used in a humid ammonia environment or a corrosive environment containing certain ammonium salts and acetylene, as well as moist fluorine gas, chlorine gas, or other types of heavy In the medium environment of chemical substances such as chromate and potassium chloride, it is very susceptible to chemical corrosion, and some chemical substances in the medium will have some chemical reactions with the explosion-proof wrench itself, which will generate some explosive substances with a high-risk factor. For example, the interaction of acetylene and steel will produce acetylene steel that is easy to explode. Therefore, when using non-sparking wrenches, pay attention to a dry and clean environment and speed up the use and operation. , To shorten the operation time to avoid more significant corrosive hazards. Not only that, after using the non-sparking wrench, wipe the metal surface of the twist in time, and it is not possible to put the non-sparking wrench and corrosive chemical media together. Not only that, the tensile strength of the bronze non-sparking wrench must be greater than 105kgf/mm2, and it must be antimagnetic. Marine non-spark explosion-proof tool manufacturer adheres to the concept of serving customers first. For 20 years, it has been professionally making non-spark explosion-proof tools. If you trust the ocean, you will get an excellent non-spark explosion-proof tool manufacturer. |

|

|

|

|

|

|

|

|

|

|

|

|

Q1: Are you Manufacturer or trading company?

A: We are Manufacturer with 38 years experience. Our main products:Non-sparking Tools/Non-magnetic Tools/ Titanium Tools/Stainless Steel Tools/ VDE insulated tools/Jumbo CRV Tools.

Q2. Can I have a sample order?

A: Yes we offer sample, you will check quality before bulk order.We can send sample order by DHL/TNT/UPS/Fedex etc.

Q3: How long will I expect to receive the sample?

A: We can send samples by Express (DHL, FedEx, UPS, TNT), normally it will take 7-14 days.

Q4: How long is the delivery time for bulk order?

A: It depends on the order quantity, normally the delivery time will be 15-45 working days.Pls kindly contact us before order.

Q5: OEM/ODM service available?

A: Yes,we accept OEM/ODM.

Q6: Do you have MOQ?

A: No MOQ.

Q: If I need customize Packing Cartons,is that available.

A:Yes,we have production line for packing box and cartons.we can make it according to your special requirement.

Q7: How to guarantee the Quality.

A:Yes,we have strict control of the quality from the raw material to finished products according to ISO9001 QC system.

We guarantee all products are 100% qualified and backed by lifetime warranty.

Q8:How will you delivery my order?

A: Normally for the order quantity less than 45 kgs, we send by Express; from 45-200kgs we suggest to send by Air. For Bulk order,we will send by Sea.It all depends,we will compare and find the best solutions.

Q9:Which countries are you exported to?

We exported to more than 110 countries around the world. We have set up agents and distributors worldwide to supply good service.

PRODUCT MESSAGE

HAYONEXTOOLS

Main Product series:

-

Non sparking wrench

-

Non sparking sleeve and accessories

-

Non sparking pliers

-

Non sparking screwdriver

-

Non sparking axe hammer

-

Non sparking cutting tools

-

Non sparking prychisel

-

Non sparking other

-

Non sparking suit class

-

Titanium alloy series

-

Electrostatic product series

-

Non sparking insulation tools

-

Antimagnetic tool series

-

Special tools

QR Code

Copyright cangzhou marine Explosion-proof Special Tools Manufacturing Co., LTD. All Rights Reserved 冀ICP备15030298号-7 Powered by www.300.cn shijiazhuang