Principle of non-sparking combination wrench

- Categories:Industry dynamic

- Author:Lisa

- Origin:

- Time of issue:2023-01-14

- Views:0

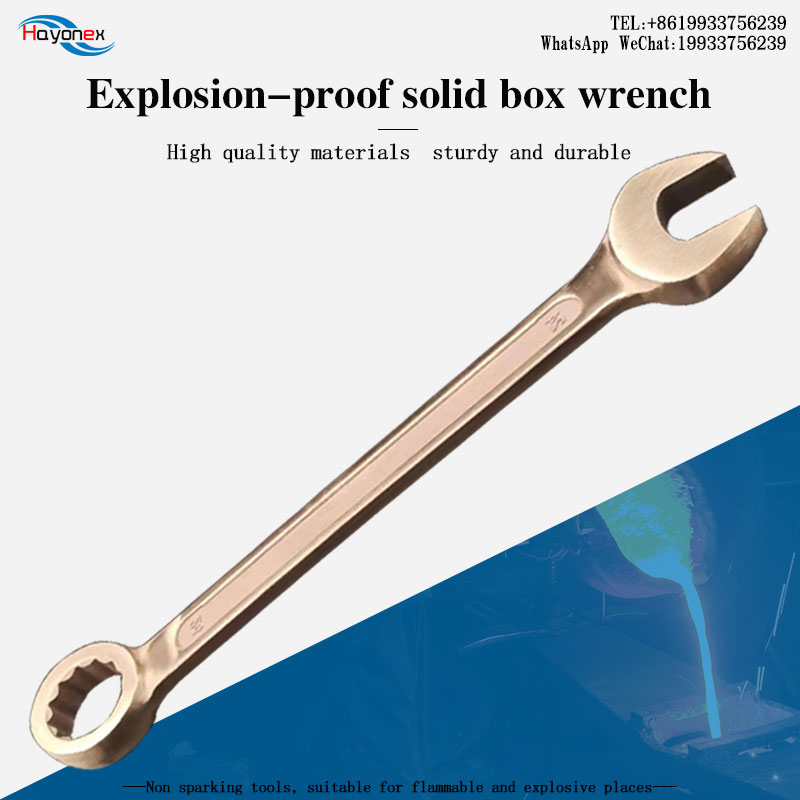

(Summary description)Explosion-proof combination wrench: one end is the same as the single-end solid wrench, the other end is the same as the box wrench, and the bolts or nuts of the same specification are screwed at both ends. Explosion-proof combination wrench is made of beryllium bronze and aluminum bronze alloy materials. The product specifications are: 6-7-8-9-10-11-12-13-15-16-17-18-19-20-21-22-23-24-24-26-27-30-32-34-36-38-41-46-50-55-60-65-70mm. Scope of application of explosion-proof dual-use wrench: it can be widely used in petroleum, petrochemical, oil station, oil depot, gas production, chemical, military, electric power, mine, electronics, railway, and other dangerous environments with potential fire and explosion, and is also an indispensable special tool for machinery manufacturing and machinery maintenance The tensile strength of beryllium bronze products processed by explosion-proof dual-use wrenches can reach more than 35 degrees, and the products made of this material can be antimagnetic, so this product is both explosion-proof and antimagnetic, especially suitable for using aluminum bronze explosion-proof dual-use wrenches in workplaces with higher requirements. The tensile strength of explosion-proof dual-use wrenches can reach more than 25 degrees. Explosion-proof dual-use wrenches are commonly used wrenches. After processing in the machining workshop, A series of tests will be carried out. Appearance quality inspection of explosion-proof combination wrench: the wrench surface shall be free of cracks, burrs, obvious cracks, cuts, scale and other defects, and the handle shall be flat and straight. Dimension inspection: the overall dimension of the wrench shall comply with the relevant provisions of GB4388 and GB4389. The tolerance of wrench opening and wrench hole shall comply with GB4390 standard. Explosion-proof dual-use wrench product specification: S6-S55MM. It has the characteristics of reasonable design, stable structure, high material density, strong resistance to impact, no folding, continuous, no bending, high dimensional accuracy and durability.

Principle of non-sparking combination wrench

(Summary description)Explosion-proof combination wrench: one end is the same as the single-end solid wrench, the other end is the same as the box wrench, and the bolts or nuts of the same specification are screwed at both ends. Explosion-proof combination wrench is made of beryllium bronze and aluminum bronze alloy materials. The product specifications are: 6-7-8-9-10-11-12-13-15-16-17-18-19-20-21-22-23-24-24-26-27-30-32-34-36-38-41-46-50-55-60-65-70mm. Scope of application of explosion-proof dual-use wrench: it can be widely used in petroleum, petrochemical, oil station, oil depot, gas production, chemical, military, electric power, mine, electronics, railway, and other dangerous environments with potential fire and explosion, and is also an indispensable special tool for machinery manufacturing and machinery maintenance The tensile strength of beryllium bronze products processed by explosion-proof dual-use wrenches can reach more than 35 degrees, and the products made of this material can be antimagnetic, so this product is both explosion-proof and antimagnetic, especially suitable for using aluminum bronze explosion-proof dual-use wrenches in workplaces with higher requirements. The tensile strength of explosion-proof dual-use wrenches can reach more than 25 degrees. Explosion-proof dual-use wrenches are commonly used wrenches. After processing in the machining workshop, A series of tests will be carried out. Appearance quality inspection of explosion-proof combination wrench: the wrench surface shall be free of cracks, burrs, obvious cracks, cuts, scale and other defects, and the handle shall be flat and straight. Dimension inspection: the overall dimension of the wrench shall comply with the relevant provisions of GB4388 and GB4389. The tolerance of wrench opening and wrench hole shall comply with GB4390 standard. Explosion-proof dual-use wrench product specification: S6-S55MM. It has the characteristics of reasonable design, stable structure, high material density, strong resistance to impact, no folding, continuous, no bending, high dimensional accuracy and durability.

- Categories:Industry dynamic

- Author:Lisa

- Origin:

- Time of issue:2023-01-14

- Views:0

Explosion-proof combination wrench: one end is the same as the single-end solid wrench, the other end is the same as the box wrench, and the bolts or nuts of the same specification are screwed at both ends. Explosion-proof combination wrench is made of beryllium bronze and aluminum bronze alloy materials. The product specifications are: 6-7-8-9-10-11-12-13-15-16-17-18-19-20-21-22-23-24-24-26-27-30-32-34-36-38-41-46-50-55-60-65-70mm. Scope of application of explosion-proof dual-use wrench: it can be widely used in petroleum, petrochemical, oil station, oil depot, gas production, chemical, military, electric power, mine, electronics, railway, and other dangerous environments with potential fire and explosion, and is also an indispensable special tool for machinery manufacturing and machinery maintenance The tensile strength of beryllium bronze products processed by explosion-proof dual-use wrenches can reach more than 35 degrees, and the products made of this material can be antimagnetic, so this product is both explosion-proof and antimagnetic, especially suitable for using aluminum bronze explosion-proof dual-use wrenches in workplaces with higher requirements. The tensile strength of explosion-proof dual-use wrenches can reach more than 25 degrees. Explosion-proof dual-use wrenches are commonly used wrenches. After processing in the machining workshop, A series of tests will be carried out. Appearance quality inspection of explosion-proof combination wrench: the wrench surface shall be free of cracks, burrs, obvious cracks, cuts, scale and other defects, and the handle shall be flat and straight. Dimension inspection: the overall dimension of the wrench shall comply with the relevant provisions of GB4388 and GB4389. The tolerance of wrench opening and wrench hole shall comply with GB4390 standard. Explosion-proof dual-use wrench product specification: S6-S55MM. It has the characteristics of reasonable design, stable structure, high material density, strong resistance to impact, no folding, continuous, no bending, high dimensional accuracy and durability.

Scan the QR code to read on your phone

HAYONEXTOOLS

Main Product series:

-

Non sparking wrench

-

Non sparking sleeve and accessories

-

Non sparking pliers

-

Non sparking screwdriver

-

Non sparking axe hammer

-

Non sparking cutting tools

-

Non sparking prychisel

-

Non sparking other

-

Non sparking suit class

-

Titanium alloy series

-

Electrostatic product series

-

Non sparking insulation tools

-

Antimagnetic tool series

-

Special tools

QR Code

Copyright cangzhou marine Explosion-proof Special Tools Manufacturing Co., LTD. All Rights Reserved 冀ICP备15030298号-7 Powered by www.300.cn shijiazhuang