Why Non sparking Box Wrench Can Become a Special Tool for Natural Gas Maintenance

- Categories:News

- Author:Lisa

- Origin:

- Time of issue:2022-11-24

- Views:0

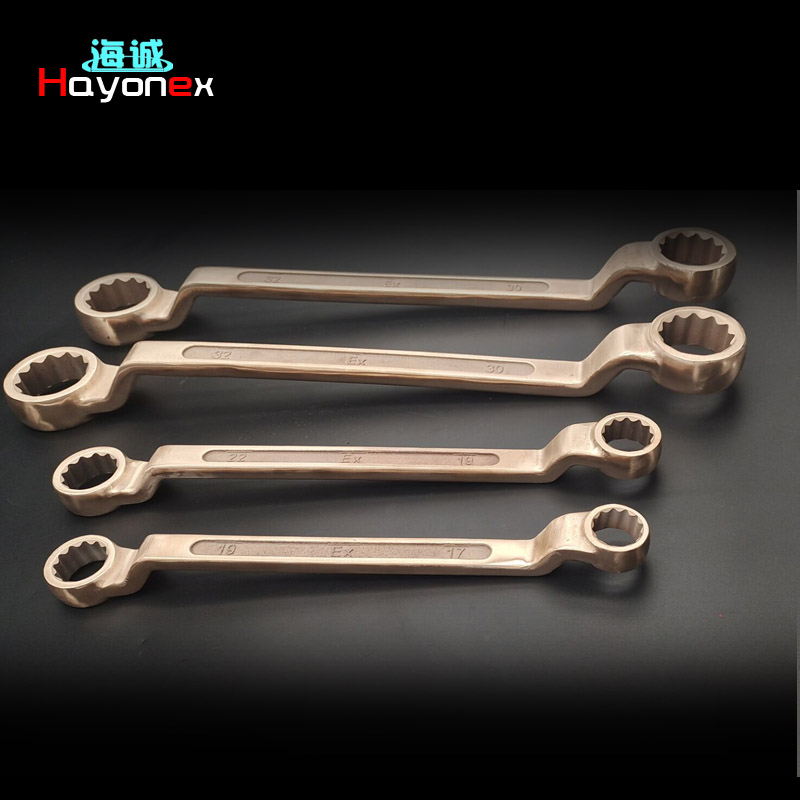

(Summary description)As an ordinary hand tool, box spanner is widely used in daily life, machinery manufacturing and machinery maintenance. The explosion-proof box wrenches used in gas stations and gas maintenance are fundamentally different from the ordinary box wrenches in terms of material. The ordinary box wrenches are made of 45 # steel or stainless steel, which is easy to produce sparks after being knocked in use and cannot play the explosion-proof function. The explosion-proof box wrench is made of high-quality beryllium bronze or aluminum bronze as raw materials. The explosion-proof box wrench is made of II C beryllium bronze, which does not detonate gas when operating in hydrogen with a concentration of 21%; Another aluminum bronze explosion-proof box spanner, which belongs to IIB product, does not detonate gas when operating in ethylene gas with a concentration of 7.8%. Beryllium bronze tools, also known as antimagnetic tools, can work safely in the magnetic field environment because of its zero magnetism. The explosion-proof products of these two materials can play the explosion-proof function after processing. And beryllium bronze alloy products are both explosion-proof and antimagnetic products, which are particularly suitable for use in places with stricter requirements. The performance of explosion-proof box wrench is also reflected in its good tensile strength. The tensile strength of aluminum bronze explosion-proof box wrench can reach more than 25 degrees, and the tensile strength of beryllium bronze explosion-proof box wrench can reach more than 35 degrees. These two explosion-proof box wrench products with different strengths are available for customers to choose different workplaces to use our explosion-proof tools

Why Non sparking Box Wrench Can Become a Special Tool for Natural Gas Maintenance

(Summary description)As an ordinary hand tool, box spanner is widely used in daily life, machinery manufacturing and machinery maintenance. The explosion-proof box wrenches used in gas stations and gas maintenance are fundamentally different from the ordinary box wrenches in terms of material. The ordinary box wrenches are made of 45 # steel or stainless steel, which is easy to produce sparks after being knocked in use and cannot play the explosion-proof function. The explosion-proof box wrench is made of high-quality beryllium bronze or aluminum bronze as raw materials. The explosion-proof box wrench is made of II C beryllium bronze, which does not detonate gas when operating in hydrogen with a concentration of 21%; Another aluminum bronze explosion-proof box spanner, which belongs to IIB product, does not detonate gas when operating in ethylene gas with a concentration of 7.8%. Beryllium bronze tools, also known as antimagnetic tools, can work safely in the magnetic field environment because of its zero magnetism. The explosion-proof products of these two materials can play the explosion-proof function after processing. And beryllium bronze alloy products are both explosion-proof and antimagnetic products, which are particularly suitable for use in places with stricter requirements. The performance of explosion-proof box wrench is also reflected in its good tensile strength. The tensile strength of aluminum bronze explosion-proof box wrench can reach more than 25 degrees, and the tensile strength of beryllium bronze explosion-proof box wrench can reach more than 35 degrees. These two explosion-proof box wrench products with different strengths are available for customers to choose different workplaces to use our explosion-proof tools

- Categories:News

- Author:Lisa

- Origin:

- Time of issue:2022-11-24

- Views:0

As an ordinary hand tool, box spanner is widely used in daily life, machinery manufacturing and machinery maintenance. The explosion-proof box wrenches used in gas stations and gas maintenance are fundamentally different from the ordinary box wrenches in terms of material. The ordinary box wrenches are made of 45 # steel or stainless steel, which is easy to produce sparks after being knocked in use and cannot play the explosion-proof function. The explosion-proof box wrench is made of high-quality beryllium bronze or aluminum bronze as raw materials. The explosion-proof box wrench is made of II C beryllium bronze, which does not detonate gas when operating in hydrogen with a concentration of 21%; Another aluminum bronze explosion-proof box spanner, which belongs to IIB product, does not detonate gas when operating in ethylene gas with a concentration of 7.8%. Beryllium bronze tools, also known as antimagnetic tools, can work safely in the magnetic field environment because of its zero magnetism. The explosion-proof products of these two materials can play the explosion-proof function after processing. And beryllium bronze alloy products are both explosion-proof and antimagnetic products, which are particularly suitable for use in places with stricter requirements. The performance of explosion-proof box wrench is also reflected in its good tensile strength. The tensile strength of aluminum bronze explosion-proof box wrench can reach more than 25 degrees, and the tensile strength of beryllium bronze explosion-proof box wrench can reach more than 35 degrees. These two explosion-proof box wrench products with different strengths are available for customers to choose different workplaces to use our explosion-proof tools

Scan the QR code to read on your phone

HAYONEXTOOLS

Main Product series:

-

Non sparking wrench

-

Non sparking sleeve and accessories

-

Non sparking pliers

-

Non sparking screwdriver

-

Non sparking axe hammer

-

Non sparking cutting tools

-

Non sparking prychisel

-

Non sparking other

-

Non sparking suit class

-

Titanium alloy series

-

Electrostatic product series

-

Non sparking insulation tools

-

Antimagnetic tool series

-

Special tools

QR Code

Copyright cangzhou marine Explosion-proof Special Tools Manufacturing Co., LTD. All Rights Reserved 冀ICP备15030298号-7 Powered by www.300.cn shijiazhuang